EXPLORE SOME OF OUR PAST PROJECTS

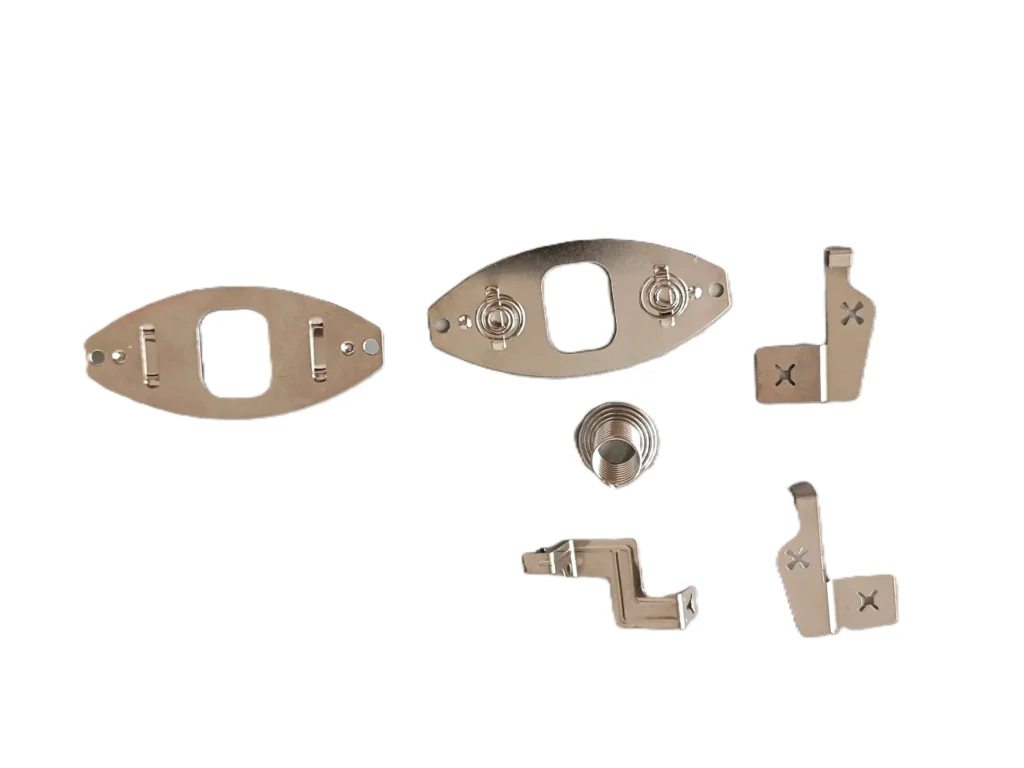

Stamping/forging parts

-Material:silver,copper,aluminum,steel(high flexible or standard type),etc.

-Machinary:from 10T to 160T;

-Finished:sandblasting,ultrasonic cleaning;

-Au/Ni plating,painting,anodization(hardened/standard),powder coating etc;

-Applications:security products(camera,monitor…),Payment devices,home applicance;

-Measurement:3D measurement device.

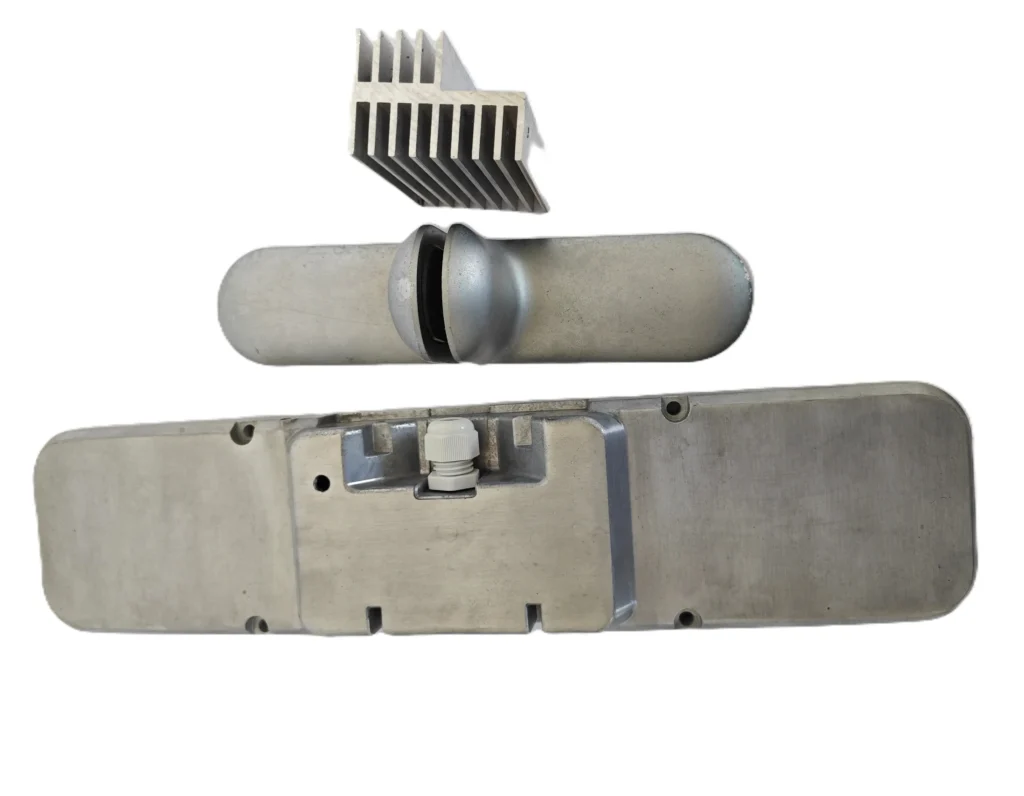

Diecasting parts

-Material:ADC12(aluminum alloy) etc;

-Machinary:from 160T-800T;

-Finished:sandblasting,ultrasonic cleaning;

-Chromate plating,painting,powder coating etc.

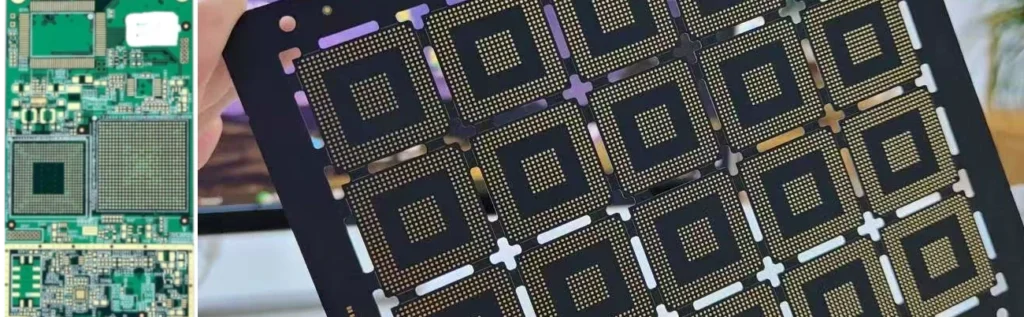

PCB assembly

– Visual inspection: general quality inspection

– X-ray test: check whether there is short-circuit cold welding or bubble problem in BGA, QFN, and another welding.

– Automatic optical detection: check whether there are false welding, short circuit, few parts, polarity reversal, etc.

– Online testing.

– Function test (according to the test steps you provided)

PCB

– Layer: from 1 to 70.

– Max board size: 2 layers: 1500*570mm, >=4layers: 570*1200mm(Need to evaluate when length is over 570mm).

– Max.array size for PTFE material(Thick<=0.5mm):16*18 inch.

– Copper thickness: from 1/3Oz to 12Oz.

– Surface finishing: HASL Lead free, ENIG, OSP, Immersion Tin, Immersion Silver, Gold plating, Tin plating.

-Gold thickness with hard gold plating: from 0.1um to 1.3um.

-Min diameter for BGA pad: 7mil.

-01

– 02

– 03

– 04